|

Visit our web shop! |

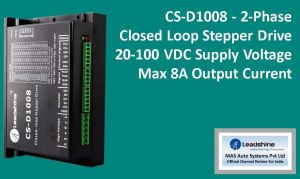

Leadshine CS-D1008 closed loop stepper motor controller (1163)

Webshop

» Electronics

» Stepper motor with encoder and controller

» Leadshine CS-D1008 closed loop stepper motor controller

https://shop.cncdrive.hu/product/1163-leadshine-cs-d1008-closed-loop-stepper-motor-controller

Price:

Leadshine CS-D1008 closed loop stepper motor controller

Leadshine CS-D1008 closed loop stepper motor controller specifications

Closed loop stepper motor driver Leadshine CS-D1008 20-100V 8A

Power input: 20-100V DC

Max. 8A current

Max. 8A current

The

Leadshine CS series is a cost-effective alternative for applications

where servo was previously the only choice due to high performance and

reliability requirements.

The system consists of a 3-phase stepper motor with a fully

digital, high-performance controller and an internal encoder. Real-time

position, speed and current are monitored in a control loop similar to

servo systems. Hybrid servos combine the advantages of servo and stepper

motor technologies. They provide unique features and improvements over

these conventional systems at a lower cost than servo systems.The connection is very simple: the motor is connected to the drive in the same way as a stepper motor (4 wires), the encoder is connected to the drive by a separate cable. The encoder cables are available in different lengths and are suitable for motors. Our digital drive adapters fit the encoder signals, so the drive can be easily connected to ELS or Beamicon CNC controllers via Ethernet patch cable. The adapters also fit other CNC controllers such as Breakoutboard for Edging or Mach 3,UCCNC but you can also connect the drive directly to other systems.

It's fast, powerful and very reliable, and unlike some cheap Ebay or Alibaba offerings, it's easy to use: plug and play.

No tuning required.

Product description:

- Closed loop, eliminates step loss Wider operating range

- Greater torque and higher speed

- Reduced heat production and increased efficiency

- Smooth running and very quiet operation

- The design requires significantly less torque reserve than conventional stepping motors

- No adjustment and always stable

- Very low response time

- High torque at start-up and low revs, high stiffness at standstill

- Cost effective

- Brake resistor can be connected (adjustable in software)

Suitable hybrid servo motors:

What are closed loop stepping motors?

Closed loop stepper motors combine the advantages of stepper and servo motor technology. They run smoother and have lower resonance than stepper motors, provide position feedback and control, short settling and damping times, and no longer exhibit step loss. They are an alternative to stepper motors when energy efficiency, smooth running and high load capacity are required. Compared to servo motors, they offer the advantages of high torque at low speeds, short set-up times, correct positioning without hunting and lower price, often in a smaller size.

When a closed-loop stepper motor is a good alternative?

- When you need high torque up to 1000 rpm and a compact, low-cost solution without the need for a gearbox.

- When you need simple and quick installation without complicated tuning.

- When a low-cost drive is needed as an alternative to servo motors.

- When a load has to be held stationary (e.g. Z-axis of a milling machine).

- When the typical behaviour of servomotors leads to tracking errors that are intolerable for the application. Servomotors overshoot their position in the event of sudden load changes, which then need to be compensated.